Table of Contents

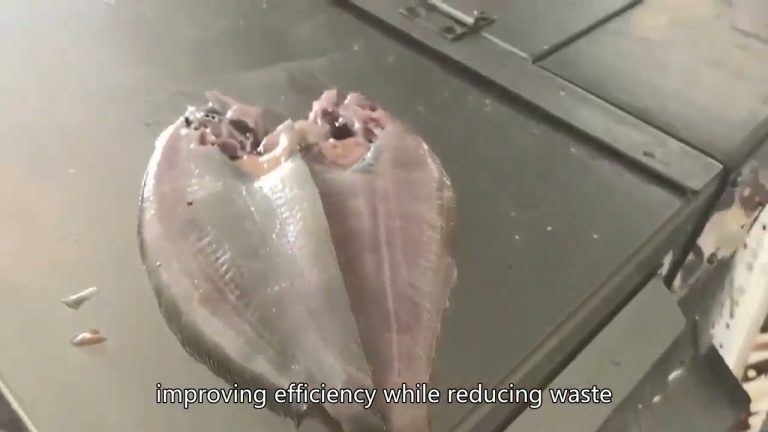

Understanding Fish Fillet Processing Machines

Fish fillet processing machines are essential in the seafood industry, as they streamline the process of converting whole fish into fillets. These machines are designed to increase efficiency and reduce labor costs by automating various steps in the filleting process. From skinning and boning to cutting and packaging, each machine plays a crucial role in ensuring consistent quality and maximizing yield.

| Serial Nr. | Name |

| 1 | Fish processing machinery |

| 2 | Descaling machine |

| 3 | Fillet fish making machine |

| 4 | Fresh fish cutting machine |

| 5 | fish skin peeling machine |

| 6 | Fish washing machinery |

| 7 | Frozen fish Ice Glazer |

| 8 | Fish gutting device |

| 9 | Fish depressing machine |

| 10 | Cuting fish slicer |

When considering the purchase of a fish fillet processing machine, it is important to understand the different types available. Some machines are specifically designed for small-scale operations, while others can handle large volumes. Factors such as production capacity, ease of use, and maintenance requirements are critical to evaluate before making a decision.

Factors Influencing Wholesale Prices

The wholesale price of fish fillet processing machines can vary significantly based on several factors. One of the primary considerations is the technology used in the machine. Advanced models equipped with the latest automation features typically come at a higher price point. However, they often provide greater efficiency and reduced operational costs over time.

Another factor that influences pricing is the manufacturer’s reputation and the machine’s build quality. Established brands with a history of reliability may charge more, but their products often come with better warranties and support services. Additionally, the materials used in construction, such as stainless steel versus plastic, can impact the overall cost.

Benefits of Buying in Bulk

Purchasing fish fillet processing machines in bulk can lead to significant cost savings. Wholesale purchasing allows businesses to take advantage of lower unit prices, which can be particularly beneficial for companies looking to expand their operations or upgrade their existing equipment. This strategy can also provide leverage in negotiating better terms with suppliers.

Furthermore, buying in bulk often means that companies can receive additional services, such as installation and training, bundled into the deal. This not only ensures that the machines are set up correctly but also helps staff become proficient in their use, further enhancing productivity and minimizing downtime.