Table of Contents

생선 절단 기계의 중요성

생선 절단기는 다양한 요리 목적으로 물고기를 준비하는 과정을 간소화함으로써 해산물 가공 산업에서 중요한 역할을합니다. 이 기계는 다양한 종류의 물고기 유형의 생선을 효율적이고 정확하게 자르고, 슬라이스하고, 필렛하도록 설계되어 해산물 가공 업체의 시간과 인건비를 절약 할 수 있습니다.

어류 절단 기계를 사용하면 해산물 가공 회사는 어류 삭감의 크기와 모양이 균일 한 상태를 보장하여 일관된 제품 품질로 이어질 수 있습니다. 이는 프레젠테이션 및 부분 제어가 핵심 요소 인 국내 및 국제 시장의 표준과 요구 사항을 충족시키는 데 필수적입니다.

어류 절단기는 수동 절단의 필요성을 줄임으로써 작업장 안전을 개선하는 데 도움이되며, 이는 날카로운 나이프와 반복적 인 모션으로 인해 위험 할 수 있습니다. 절단 과정을 자동화함으로써 근로자는 잠재적 인 부상을 피하고 해산물 가공 공장의 다른 중요한 작업에 집중할 수 있습니다.

생선 절단 기계의 종류

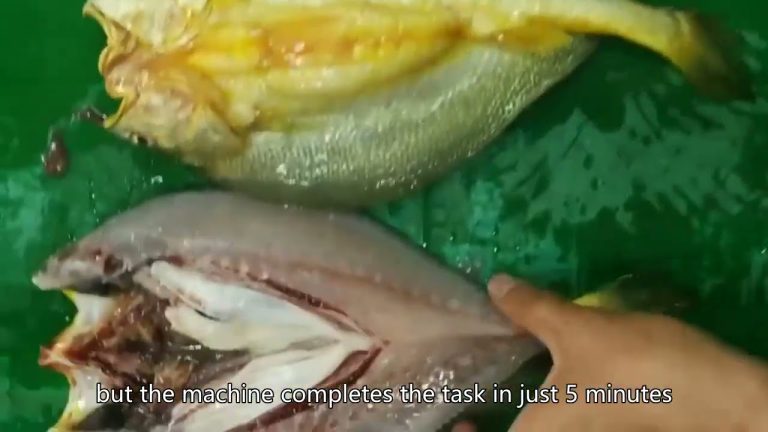

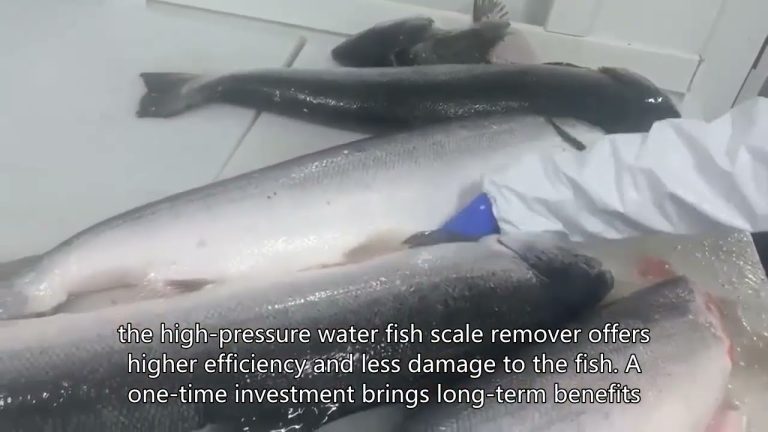

시장에는 여러 가지 유형의 어류 절단 기계가 있으며, 각각은 가공중인 물고기의 크기와 종을 기반으로 특정 절단 작업을 위해 설계되었습니다. 일반적인 유형 중 하나는 물고기 필레팅 기계입니다.이 필트 기계는 정밀도와 속도로 생선 필레에서 뼈와 피부를 제거하는 데 사용됩니다.

다른 인기있는 유형은 생선 슬라이싱 머신입니다. 이는 소매 포장 또는 추가 가공을 위해 생선을 균일 한 두께 조각으로 자르는 데 이상적입니다. 이 기계에는 다양한 절단 요구 사항을 수용 할 수있는 조정 가능한 설정이 장착되어있어 해산물 가공 시설에서 다양한 도구가 제공됩니다.

| 일련 번호 | 옵션 |

| 1 | 물고기 가공 공장 |

| 2 | 물고기 하강 장치 |

| 3 | 피쉬 필렛 기계 자동 |

| 4 | 자동 밴드는 얼어 붙은 생선 절단 기계를 보았습니다. |

| 5 | 생선 피부 필링 머신 |

| 6 | 생선 세척 장치 |

| 7 | 해산물 얼음 유약 기계 |

| 8 | 피쉬 gutting machinery |

| 9 | 물고기 우울 기계 |

| 10 | 생선 슬라이서 절단 기계 |

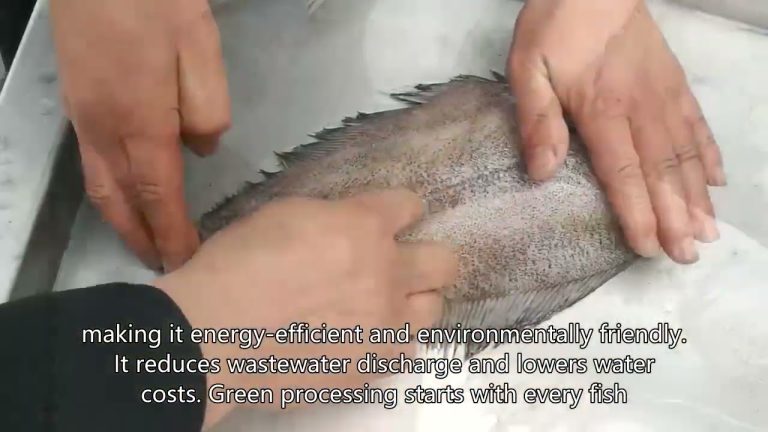

필레 팅 및 슬라이싱 머신 외에도 스케일링, gutting 및 부분 물고기와 같은 작업을위한 특수 어류 절단 기계가 있습니다. 이 기계는 해산물 가공 운영의 효율성과 생산성을 극대화하는 데 필수적이므로 기업이 경쟁 시장의 요구를 충족시킬 수 있습니다.