Table of Contents

Overview of Fish Open Machine Factories

Fish open machine factories represent a significant advancement in the aquaculture industry. These facilities are designed to optimize the processing of fish, utilizing cutting-edge technology to enhance efficiency and maintain high standards of quality. With the increasing global demand for seafood, such factories play a crucial role in meeting market needs while ensuring sustainability.

In these factories, various machines work seamlessly to automate processes such as cleaning, filleting, and packaging. This automation not only speeds up production but also minimizes human error, leading to better product consistency. The use of open machinery allows for easier maintenance and cleaning, which is vital in an industry where hygiene standards are paramount.

Technological Innovations in Fish Processing

The integration of advanced technologies within fish open machine factories has revolutionized traditional methods of fish processing. Sensors and AI-driven systems are employed to monitor fish quality in real-time, ensuring that only the best products reach consumers. Such innovations help producers address issues such as spoilage and contamination, ultimately enhancing food safety.

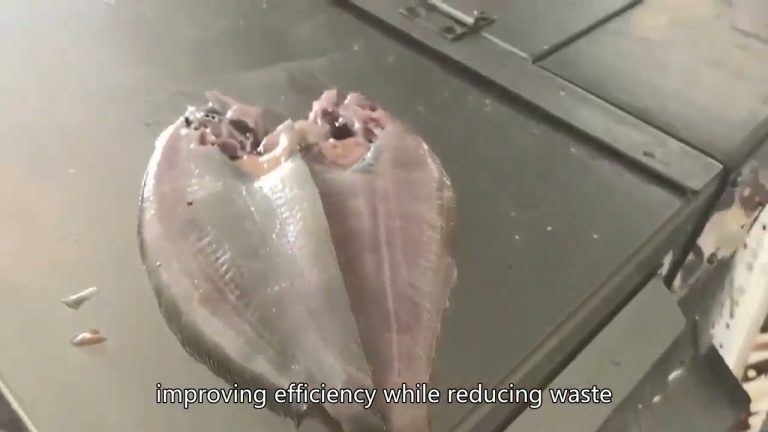

Additionally, robotic systems are increasingly being used for tasks that require precision and speed, such as portioning and packing. These robots can operate continuously without fatigue, which increases overall productivity. The implementation of machine learning algorithms further optimizes the production process by analyzing data to predict maintenance needs and streamline operations.

Sustainability Practices in Fish Open Machine Factories

Sustainability is a core principle guiding the operations of modern fish open machine factories. Many facilities prioritize sourcing fish from sustainable fisheries, ensuring that their practices do not deplete resources or harm marine ecosystems. By adhering to responsible sourcing guidelines, these factories contribute positively to the health of our oceans.

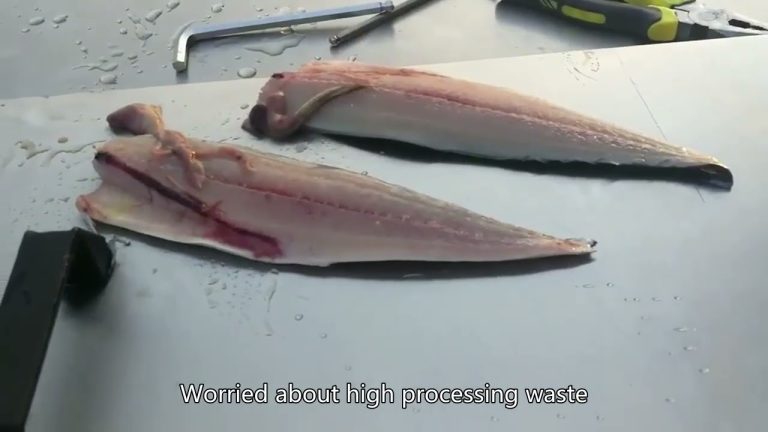

Moreover, many factories are investing in energy-efficient machinery and waste reduction strategies. For instance, by recycling water used in processing and utilizing by-products for other purposes, they minimize their environmental footprint. This commitment to sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers who are increasingly seeking responsibly sourced seafood.

| Serial Number | Options |

| 1 | Fish processing device |

| 2 | Tumbleing fish scaler machine |

| 3 | Machine fish fillet |

| 4 | Fresh fish cutting machine |

| 5 | Fish peeling equipment |

| 6 | Fish cleaning machine automatic |

| 7 | Frozen fish Ice Glazer |

| 8 | Fish scaling and gutting machine |

| 9 | Fresh fish meat picker |

| 10 | Fish slicer machine cutting |