Table of Contents

Overview of Tilapia Filleting Machines

Tilapia filleting machines are specialized equipment designed to streamline the process of preparing this popular fish for consumption. These machines automate the labor-intensive task of filleting, ensuring consistency and efficiency in fish processing operations. With the growing demand for tilapia globally, the need for advanced filleting solutions has become increasingly important.

| Number | Commodity name |

| 1 | Fish processing equipment |

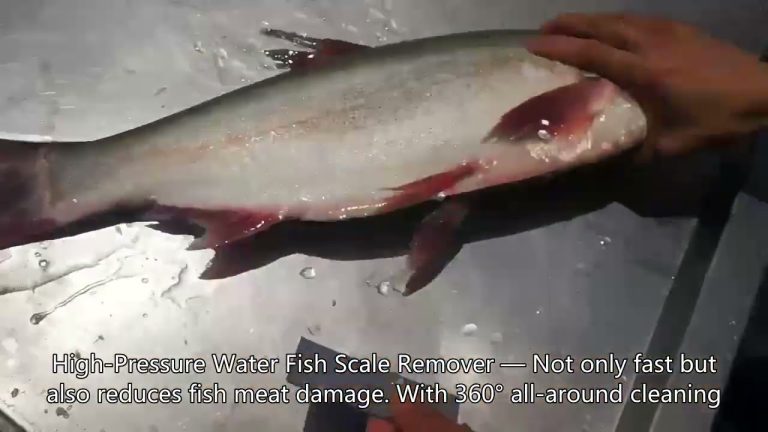

| 2 | Fish skin water scaling machine |

| 3 | Automatic fish filleting machinery |

| 4 | Fresh fish cutting machine |

| 5 | Fish skin removal equipment |

| 6 | Fish cleaning machine automatic |

| 7 | Frozen fish Ice Glazer |

| 8 | Fish killing scaling gutting filleting machine |

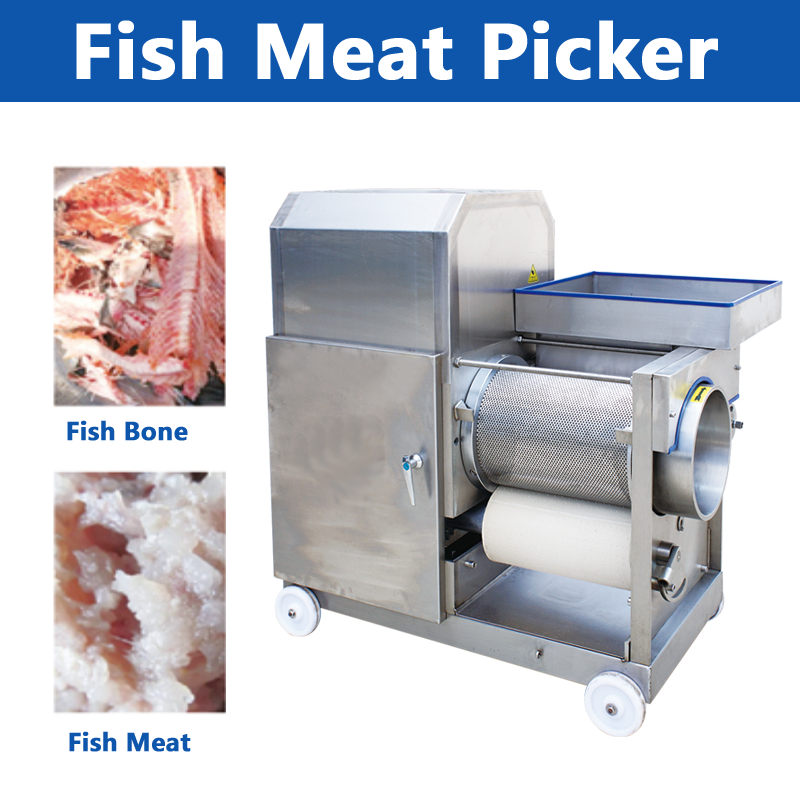

| 9 | Fresh fish meat picker |

| 10 | Fish slicer machine |

The technology behind tilapia filleting machines has evolved significantly in recent years. Modern machines incorporate features such as precision cutting blades and adjustable settings that cater to different sizes and types of tilapia. This adaptability allows factories to maximize their output while maintaining high quality in their product.

Leading Tilapia Filleting Machine Factories

Several factories around the world specialize in manufacturing tilapia filleting machines. These facilities utilize cutting-edge technology and adhere to strict quality control standards to produce reliable equipment. Many of these factories also offer customization options to meet the specific needs of their clients, further enhancing their appeal in the competitive market.

The future of tilapia filleting machines is poised for growth, driven by advancements in automation and robotics. As more factories adopt smart technologies, we can expect to see increased efficiency and reduced reliance on manual labor. This shift not only enhances productivity but also improves workplace safety, as workers are less exposed to repetitive tasks. Additionally, sustainability is becoming a focal point for many tilapia filleting machine manufacturers. The industry is exploring ways to minimize waste and energy consumption during the filleting process. Innovations such as water recycling systems and eco-friendly materials are gaining traction, reflecting a broader commitment to sustainable practices in seafood processing.